바쁜 면 공장에는 많은 사람들이 장시간 일하고 있습니다. 이러한 근로자들의 비율이 당신이 먹는 면의 맛과 즐거움을 그들의 손으로 만들어냅니다. 바깥쪽으로 보면, 공장은 거대하고 인상적입니다. 그러나 안으로 들어가면 쇼핑몰도 활기차게 느껴질 것입니다. 기계의 윙윙거림,生면이 탁자를 치는 소리, 그리고 모든 사람을 일정에 맞추기 위해 서두르는 근로자들의 모습을 들을 수 있습니다.

면을 만드는 개념은 비교적 간단하지만, 실행에는 훨씬 더 많은 노력과 주의가 필요합니다. 작업자들은 대형 기계에서大量的한 밀가루, 물 그리고 때로는 계란을 섞습니다. 그들이 그것을 잘 섞으면 부드러운生반죽이 완성됩니다. 그런 다음 반죽은 더 부드럽고 유연해지도록 눌러지고 접히며 씹히다가 됩니다. 이후에 반죽은 가늘게 썰릴 수 있도록 얇은 시트로 구르게 됩니다.

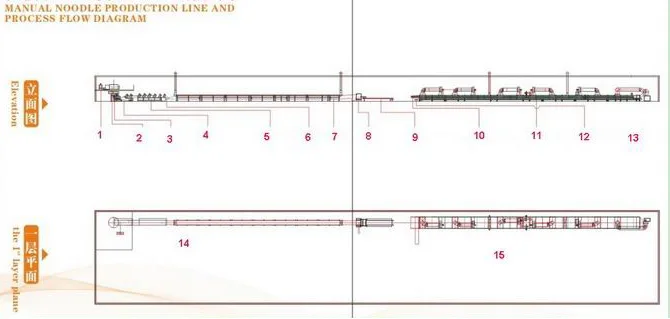

면 제조 또한 예술이자 과학이라는 점에 유의하세요. 정말 그렇습니다! 면 라인은 함께 작동하여 면을 생산하는 기계들의 조합입니다. 각 기계는 역할이 있으며, 모두가 완벽하게 작동해야 최적의 면을 얻을 수 있습니다. 하나의 기계가 고장 나면 전체 프로세스가 지연될 수 있습니다.

이런 기계들을 만드는 사람들은 물리학, 공학, 그리고 디자인에 있어 매우 숙련되고 지식이 있어야 합니다. 이러한 지식은 그들에게 매번 일관된 맛, 식감, 품질의 기계를 설계할 수 있게 해줍니다. 그들은 매우 정확해야 합니다!

기술은 우리가 다양한 것을 생산하는 방식을 크게 변화시켰지만, 전통적인 면 제조는 여전히 중요합니다. 오늘날 현대 기계는 면을 만들기를 이전보다 더 빠르게 도와줄 수 있지만, 일부 지역에서는 여전히 전통적인 방법이 사용됩니다. 예를 들어, 어떤 곳에서는 아직도 손으로 뽑아서 면을 만듭니다.

각 손으로 뽑은 면은 반죽을 계속해서 늘이고 접어서 얇고 길게 만드는 것으로 시작됩니다. 이것을 완벽하게 하는 것은 매우 어렵습니다! 우리는 이를 '삶은 덮밥'이라고 부르는데, 이는 반죽을 늘어난 후 삶아서 육즙이 가득한 국물이나 소스와 함께 제공합니다. 손으로 뽑은 면은 독특한 식감을 가지고 있으며, 많은 사람들이 그 맛을 즐긴다고 합니다.

결과적으로, 면 제조기는 더 빠르고 효과적으로 작동하도록 설계되었습니다. 수십 년 동안 수백 개의 이러한 면은 반짝이는 면 공장에서 기계에 의해 이전보다 더 많이 만들어져 왔습니다. 면 제작은 기술의 도움을 받고 있습니다!

우한 G-영 인더스트리(주)는 150명 이상의 직원을 보유한 기업입니다. 기술 관리자 10명 이상, R&D 엔지니어 20명 이상을 확보하고 있으며, R&D 팀은 품질이 높고 풍부한 실무 경험을 갖추고 있습니다. 당사는 밀가루 소비량 기준 2톤에서 14톤에 이르는 3개의 대규모 생산 공장을 보유하고 있으며, 국제적으로 선진화된 가공 설비 1,000여 대를 운영하고 있습니다. 당사는 귀사의 요구사항에 부합하는 국수 제조 라인 및 국수 기계를 공급할 수 있습니다.

우한 G-영(주)의 본사는 중국 중부 최대 도시인 우한에 위치해 있으며, 생산 기지는 중국을 대표하는 '국수 라인'으로 불리는 정저우에 자리잡고 있습니다. 당사는 기계 제조 분야에서 16년 이상의 풍부한 경험을 보유하고 있으며, 규모가 큰 공장 시설을 갖추고 있으며, 당사 제품은 20개 이상의 국가로 수출되고 있습니다.

G-YOUNG의 직원들은 고객에게 최고 품질의 장비를 제공하는 데 전념하고 있습니다. 모든 구성원은 자신의 업무에 대해 책임을 지며, 이를 진지하게 수행합니다. 원자재, 제조 공정, 완제품인 국수기까지 국수 생산 라인 및 철저한 품질 검사를 거칩니다. 당사의 기술과 노력이 여러분의 작업 환경을 더욱 향상시켜 드리기를 바랍니다.

우한 GYOUNG 산업(상표)은 인스턴트 국수 기계, 건조 국수 기계 및 기타 관련 설비를 개발, 생산 및 연구하는 평판 좋은 수출업체이자 제조업체입니다. 주요 제품으로는 튀긴 및 비튀긴 인스턴트 국수 생산 라인, 국수 걸이 시스템, 체인 케이블 방식 건조 국수 생산 라인, 생면 국수 생산 라인을 포함하여 기타 국수 생산 장비가 있습니다.

우한 G-Young 업체 무역 유한 회사 저작권 © 모든 권리 보유 - 개인정보 보호정책