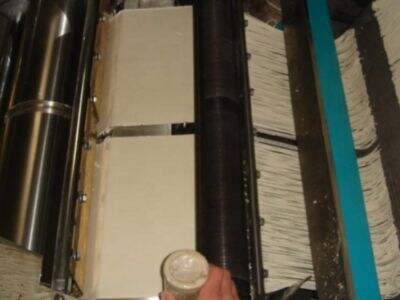

As much as I’d like to say it’s about how the dough is treated, noodle-making is an art and a science. The texture changes a lot when dough passes through machines and is pressed and shaped. GYoung’s noodle machines have a technology called multi-stage compression, which can make noodles feel better when you eat them. This means the dough is not squished once but also multiple times in stages. Every step will make the dough smoother, stronger, more elastic. That’s what happens to the inside of the dough and it gives a chewy snap so noodles come out soft but sturdy, neither too hard or too mushy. This fine squeezing explains why noodle made from GYoung, of course it improves taste and texture compared with the coarse squeezed noodles that were mostly pressed by a simple machine. It makes a noodle you want to keep biting.

Why is Multi-Stage Compression Necessary in Noodle Making Machine?

Multi-stage compression isn’t just because it sounds good; it’s an intelligent way to treat dough in noodle making. Think of what would happen if you compressed the dough really hard once. It could crack or turn tough. But when the dough is simply pressed gently many times, it has a chance to relax and settle between presses. That way, the gluten in the dough which looks like little threads gets plenty of time to move around slowly and line up just right. As it’s repressed and mixed, the dough is smoother and better textured. GYoung’s machines leverage this to ensure that all of the noodles have a pleasant chew and don’t disintegrate into crumbs when they are cooked. And the multi-step pressing is effective in driving bubbles of air out from inside the dough. Air bubbles could cause the noodles to weaken and fall apart. Disposing of them also makes noodles stronger and improves texture. We found that when we used this method, the noodles were more consistently cooked and looked shiny and new. And the dough is just moist in the right way, because we won’t compact it too dreadfully. It’s soft, not dry or sticky. What’s more, multi stage squeezing can be set according to the flower type. Thick noodles require different pressure than thin ones, for instance. GYoung noodle machine allow operators to control these steps, so it turns out to be relatively easy to make many types of noodles without having to switch machines all the time. That versatility is why multi-stage pressing is a key for good noodle making. If it were missing, noodles would be uneven or not as delicious.

Where To Get Wholesale Noodle Machines With Superior Multi-Phase Pressing

If you are looking for to purchase noodle machines that employ this intelligent multi-stage compression then your choice would be GYoung. We make machines that work and work well from the little noodle shops to big factories. Our equipment is built to last and work with large quantities of dough every day. You will get noodle machines as offered by GYoung at next to half the price they are charging you in retail if you buy wholesale. Many of our customers have shared with us how easy it is to use and clean our machines, which saves time and money. Moreover, our compressors are provided with options for altering the number of compression stages. As a result, you can choose whatever is best for your noodle type, whether that’s soft, chewy or firm noodles. We know every noodle business is unique. Which is why GYoung also provides support and advice on selecting the right machine. This streamlines the buying process and ensures customers get the most out of their machines. Next time you’re on the hunt for noodle making equipment, be sure to visit GYoung’s website or get in touch with a member of our team. We respond to inquiries and even demonstrate how the machines should be used, so your noodles come out right every time. Multi-stage compression technology is part of what makes your noodle product exceptional, not just a feature. So, whether you want to enhance your noodle texture or even reduce costs. GYoung’s wholesale noodle machines are an intelligent option.

How Multi-Stage Compression Addresses Common Texture Challenges for Noodle Production

While noodles appear to be simple, the texture part can be challenging. Many noodle makers struggle with the problems of noodles that are either too soft or too hard, or those, which have inconsistent textures. The root cause of these problems can be insufficiently pressed dough during production. This is when multi-stage compression finds its importance. Multi-stage compression entails that the dough is subjected to different points of compression several times, instead of just once. This is a regular fix for a problem in noodles. If the dough receives multi-stage compression through a GYoung noodle making machine, it will be stretched and pressed out evenly. This is what strengthens and organizes the gluten inside the dough. Gluten is a protein that helps maintain the individual noodle strands and gives them a chewy, pleasant texture. If gluten is underdeveloped or broken, noodles are mushy and crumbly. And by repeating the pressing of the dough again and again, GYoung machines ensure that the gluten forms properly. Deeper in the bowels, multi-stage compression facilitates more efficient expulsion of air bubbles from dough. Bubbles of air can form holes or weak spots in noodles, causing them to break apart or cook unevenly. With multiple stages of pressing, the texture of the dough is smooth and tight so your noodles cook even better. Another issue in noodle making is that dough is pushed hard at one time. This can ruin the texture of the dough and cause your noodles to become tough or dry. Multi-stage pressing does not have this problem as soft pressing is performed through the whole process. Every stage of the process improves the dough gradually, so that it is tender but sturdy. So, in other words - multi-stage compression in GYoung noodle machines is a quick and easy way to solve those texture issues by developing gluten, DE-gassing the dough, and forming it with less force. That means your noodles are perfectly chewy, smooth and flavorful every time.

Where Weighing Up Benefits Of Multi-Stage Compression In Bulk Noodle Production

The texture is extremely difficult to sustain in all these batches of noodles she is preparing. Big noodle plants desire machine that can produce noodles in the same texture and therefore the customers would never receive a different experience. In this case, multistage compression is an aid. Dough by compressing twice using multistage compression to GYoung noodle making machine has been subjected to many pressing steps that are controlled precisely. This control will enable you to make sure that all part of the dough is receiving the same kind of treatment. When pressed an equal amount of times and evenly, persistent dough will make even noodles. This is of utmost importance to mass production, where the handling of the dough would change slightly but the quality of the end product, the noodle would change significantly. Firstly, when there are noodles of a softer and those of harder texture, customers might be less willing to like the product. Multistage compression helps to avoid the changes in the structure of gluten and moisture content. The water in the dough is called moist and how it reacts determines the feel of noodles after they are cooked. When the amount of moisture changes significantly, the noodles may become tough one day and dry the next. GYoung pasta machine which stops the moisture in more than one stage by gently pressing the dough repeatedly. This will make noodles cook evenly batch after batch. The technique also eliminates the possibility of tearing of dough or sticking on equipment. It passes through the machine in a gorgeous motion with the tender loving handling of progressive dough. This means that there is reduced breakage, spill or troubleshooting in production meaning that factories are able to continue producing noodles without incidences. Overall, the solution is multi-stage compression in GYOUNG noodle machines among the big manufacturers who prefer the same quality. Servespace Keeps the texture, moisture and shape of noodles is the same every time that will keep your customers always satisfied.

What Bulk Buyers Should Know About Multi-Stage Compression Technology

When you buy a lot of noodles to sell at a store or restaurant, then you surely must have knowledge of the significance of multiple stages of compression technology. This technology is used in GYoung noodle making machines to make your noodles better The way that matters to you The way that matters to your customers. To begin with, better-textured noodles are produced by the multi-stage compression process. The more likely customers will repurchase the noodles when they taste good but not too soft but at the same time chewy. Less deformation or breakage of the pasta products produced using this technology is likely to occur during the cooking process. Less moaning, less garbage Take that line to get more info. To wholesale purchasers, that matters a lot as that makes your commodity more stable. Second, multi-stage compression noodles are healthier and retain their freshness. The dough is pressed lightly and consistently, hence, the noodles are not dried out. This increased shelf life provides the ability to store and sell noodles without any apprehension that they will soon lose their quality. It also reduces wastages due to spoilt commodities. Third, the multi-stage compression place can also make sure that manufacturing of noodle will be constant and high-efficient. GYoung machines prepare a lot of noodles, and they could have the same perfect texture, as any of the people do at home. By doing so, wholesalers do not have to have surprises as to the supply of a good product. It is also something that is worth having, as you know that the noodles would be up to your standards every batch. Finally, an understanding of this technology would help wholesale buyers in their efforts of selling the value of their noodles to the customers. By informing the buyers that GYoung is three stage compressed, you prove the fact that your noodles are produced with great care and technology. That will build trust and could result in a sale of more noodles. multi-stage compressor technology is an easy choice by volume buyers to buy a quality, reliable and tasty noodle that consumers will desire. It improves the texture and shelf life of noodles and also enhances homogeneity of production which may strengthen your noodle business.

Table of Contents

- Why is Multi-Stage Compression Necessary in Noodle Making Machine?

- Where To Get Wholesale Noodle Machines With Superior Multi-Phase Pressing

- How Multi-Stage Compression Addresses Common Texture Challenges for Noodle Production

- Where Weighing Up Benefits Of Multi-Stage Compression In Bulk Noodle Production

- What Bulk Buyers Should Know About Multi-Stage Compression Technology

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

AZ

AZ

BN

BN

LO

LO

LA

LA

MN

MN

NE

NE

MY

MY

KK

KK

UZ

UZ