A busy noodle factory has a lot of people putting in long hours. The ratio of these workers make the noodles you eat so tasty and yummy pressed by their hands. From the outside, the factory is huge and impressive. However, once you enter inside the mall will be vibrant as well. You can hear machines buzz, dough slamming across tables and workers rushing around to keep everyone on schedule.

The concept of making noodles is fairly simple, but execution requires much more work and care than that. Workers mix large amounts of flour, water and sometimes eggs first in big machines. Have a smooth dough done as they mix it very well. Then, the dough is kneaded because it gets pressed in and folded over to soften up and become stretchy. The dough is then rolled into thin sheets so that they can be cut.

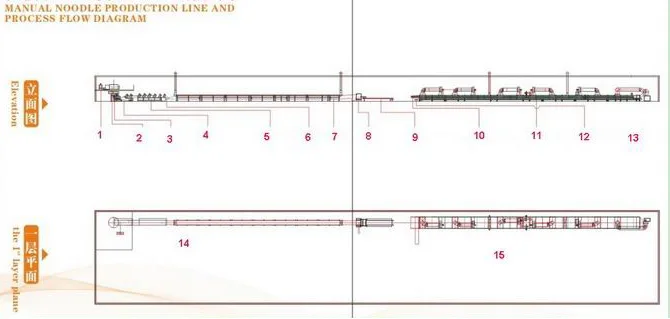

Notice that the preparation of noodles is also an art and a science. It’s true! A noodle line is the set of machines that work together to produce noodles. Every machine has a role, and the all have to be in perfect working condition for optimal noodles. If one machine is off, it can stall the entire process.

The people who make these kinds of machines must be very skilled and knowledgeable in physics, engineering, and design. This knowledge allow them to design machines which can kind of noodles in consistency, texture and quality every time. They have to be very precise!

Although technology has greatly altered the ways in which we produce any host of things, traditional noodle making is crucial. Today, modern machines can help them with the task of making noodles quicker than ever before but in some parts traditional methods are still used. For instance, in some places they still produce hand-pulled noodle.

Each hand-pulled noodle starts with stretching and folding the dough repeatedly until it is thin and long. This is very hard to perfect! Boiled dumplings, as we call them because they are boiled after the dough is stretched and served in a juicy soup or sauce. Hand-pulled noodles have a unique texture and apparently many people really enjoy their flavor.

Consequently, noodle machines are organized to ability faster and more effectively For many years, hundreds of these noodles have been made with machines that pumps more than ever in the glistening noodle factories. Noodle-making is aided by technology!important!!

WUHAN G-YOUNG INDUSTRY (tm) CO. LTD., LTD. than 150 employees. It has more than 10 Technical Managers. RD Engineers Over 20people. RD Team Has Rich Experience is of high quality. We own three huge production Plants with capacities ranging from 2tons to 14ton Wheat Flour Consumption 1000plus International Advanced Processing Equipment. can supply customers with the noodle line noodles machine meet your requirements.

The headquarters of WUHAN GYOUNG (tm) CO. LTD is located in Wuhan the biggest central Chinese city. The base of production is in Zhengzhou which is called the "noodle line" of China. We have more than 16 years of experience in the field of machinery manufacturing, a large factory space, and our products have been sold into more than 20 nations.

G-YOUNG's staff is dedicated providing customers the highest quality of equipment. Every member is accountable for his or her work and takes it seriously. The raw materials, production process finished products noodle machines will undergo noodle line and rigorous quality inspections. We hope that our technologies and efforts will bring you a better works.

WUHAN GYOUNG INDUSTRIES(tm) is a reputable exporter, manufacturer, and producer that develops, produces and researches instant noodles machines, fine-dried noodles machines and other related equipment. Our primary products include fried and non-fried instant noodle production lines, noodle line hanging systems and chain cable-style drying noodle production lines, and freshly made noodles production lines, in addition to other noodle production equipment.

Copyright © Wuhan G-Young Industry & Trade Co., Ltd. All Rights Reserved - Privacy Policy