A comprehensive guide to making instant noodles

Maggi (maggi noodles being an example) is one of them and its instant noodles has been a desirable snack for children as they are easy to make quickly. They're kinda a staple for hurried families. But do you ever wonder how those lovable noodles are actually made? Now you will explore the world of instant noodle manufacture.

How to make Instant Noodles (Step by Step)

The process of producing instant noodles is a multi-stage production. A mixture of ingredients like wheat flour, with water, salt and other optional ingredients (such as eggs or flavorings) is created initially in the preparation stage. These are then taken to a factory where.... All of these components are mixed evenly in a big mixer. Next, the paste is shaped into noodles by special rollers and cutting machinery that can be adjusted to produce many types of noodle shapes and sizes.

One that he then uses to press steam the noodles and give them both their desirable texture, as well as cook them half way. And it is this essential process which guarantees that the noodles are neither hard as rock or falling apart. After the steaming, they cool it rapidly with cold air to avoid that clumpiness. The next step is to dry the noodles, which increases its shelf life. There are two ways to dry the makafan: by frying in hot oil or air-drying with a blow of hot air.

After drying is done with, the noodles are carefully filled into extra large sleeves of cellophane bags or in one by one cups. The packets are then tightly sealed after the introduction of other delectable flavorings and seasonings. Individual packages are labeled with the brand and nutritional information.

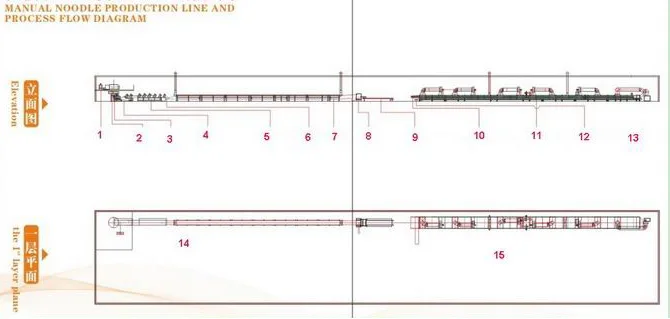

Below, there is a description of each process and related zones regarding instant noodle production facility which will occupy the large expanse in every manufacturing factory. Some section would store the base materials in a warehouse and few other of mixing and kneading machines. Steamers cooters & dryers are generally nearby in relation and the last phase of a production arrangement is being set apart for packaging sealing & labeling. Placed into these massive plants that help automate the process with a variety of big machines and conveyor belts working in tandem to put out thousands of packets quickly at one time. The workers man the production line and make sure everything is going smoothly while also making sure they maintain company quality standards.

One of the key things about producing instant noodles is that most part of it has been operating at high-speed level automation. Properly functioning machines humming away as they frantically operate in harmony to accomplish a myriad of tasks. Noodles are moved between machines by conveyor belts, with sensors and cameras monitoring for anomalies or defects. They are extremely accurate because it is a given that all packets of instant noodles must be made to the same standards. It is not only waste reduction on such an exquisite scale, but efficiency that can make the production process cost-efficient.

All About Making Instant Noodles In Bulk

The assembly line of machines, conveyor belts and labour on which instant noodles are made at vast volume. The raw materials are scientifically processed, mixed and The noodles formed Before being gracefully packaged, flavorings are added to the noodles. Noodles are made on the production line, where quality control systems protect noodles from defects thanks to automation.

At its core, though making instant noodles is a fascinating journey that consists of many steps along the way using high-tech machines. While not the healthiest diet choice, instant noodles are extremely popular; they require only a few minutes to cook and thus fit really well in helping hectic families.

WUHAN instant noodle production line INDUSTRY(tm) CO., LTD located in Wuhan the biggest city in central China. Zhengzhou is the production base which is also referred to as "noodle town in China. Our factory is spread over 1000 acres, and we have 16 years of experience in the manufacturing of machinery. We export our products to more than 20 countries.

G-YOUNG team is committed to providing the highest quality machines. Every member the G-YOUNG team seriously on duty and accountable for their daily works. Production processes, raw materials as well instant noodle production line products scrutinized for quality thorough inspections. efforts and technology should hopefully result in improved products.

WUHAN G-YOUNG INDUSTRY (tm) CO. LTD., LTD. than 150 employees. It has more than 10 Technical Managers. RD Engineers Over 20people. RD Team Has Rich Experience is of high quality. We own three huge production Plants with capacities ranging from 2tons to 14ton Wheat Flour Consumption 1000plus International Advanced Processing Equipment. can supply customers with the instant noodle production line noodles machine meet your requirements.

WUHAN GYOUNG INDUSTRIES(tm) is a reputable exporter, instant noodle production line, and producer which designs, manufactures and studies instant noodles machines, fine-dried noodles machines and similar equipment. Our main products are instant noodles, both fried and unfried production lines, low-temperature hanging and chain cable-style drying noodle lines, as well as freshly made noodles production lines, in addition to other noodle production equipment.

Copyright © Wuhan G-Young Industry & Trade Co., Ltd. All Rights Reserved - Privacy Policy